Produkter

Héichpräzis Wolframkarbid poléiert Stäb Ronnstang

Produktvirstellung

Hartmetallstangen ginn haaptsächlech fir Buerer, Endfräser a Wënschen benotzt. Si kënnen och fir Schneiden, Stanzen a Moossinstrumenter benotzt ginn. Si ginn an der Pabeier-, Verpackungs-, Dréckerei- an Nichteisenmetallveraarbechtungsindustrie benotzt. Zousätzlech gëtt se wäit verbreet fir d'Bearbechtung vun Héichgeschwindegkeetsstahlfräser, Hartmetallfräser, Hartmetallfräser, NAS-Schneidinstrumenter, Loftfaartfräser, Hartmetallboren, Fräskärboren, Héichgeschwindegkeetsstahl, Konischfräser, metresch Fräser, Mikroendfräser, Scharnierpilot, elektronescht Tool benotzt.Hartmetall-Rotatiounsfeil, Hartmetall-Tool, etc.

Produktdetailer

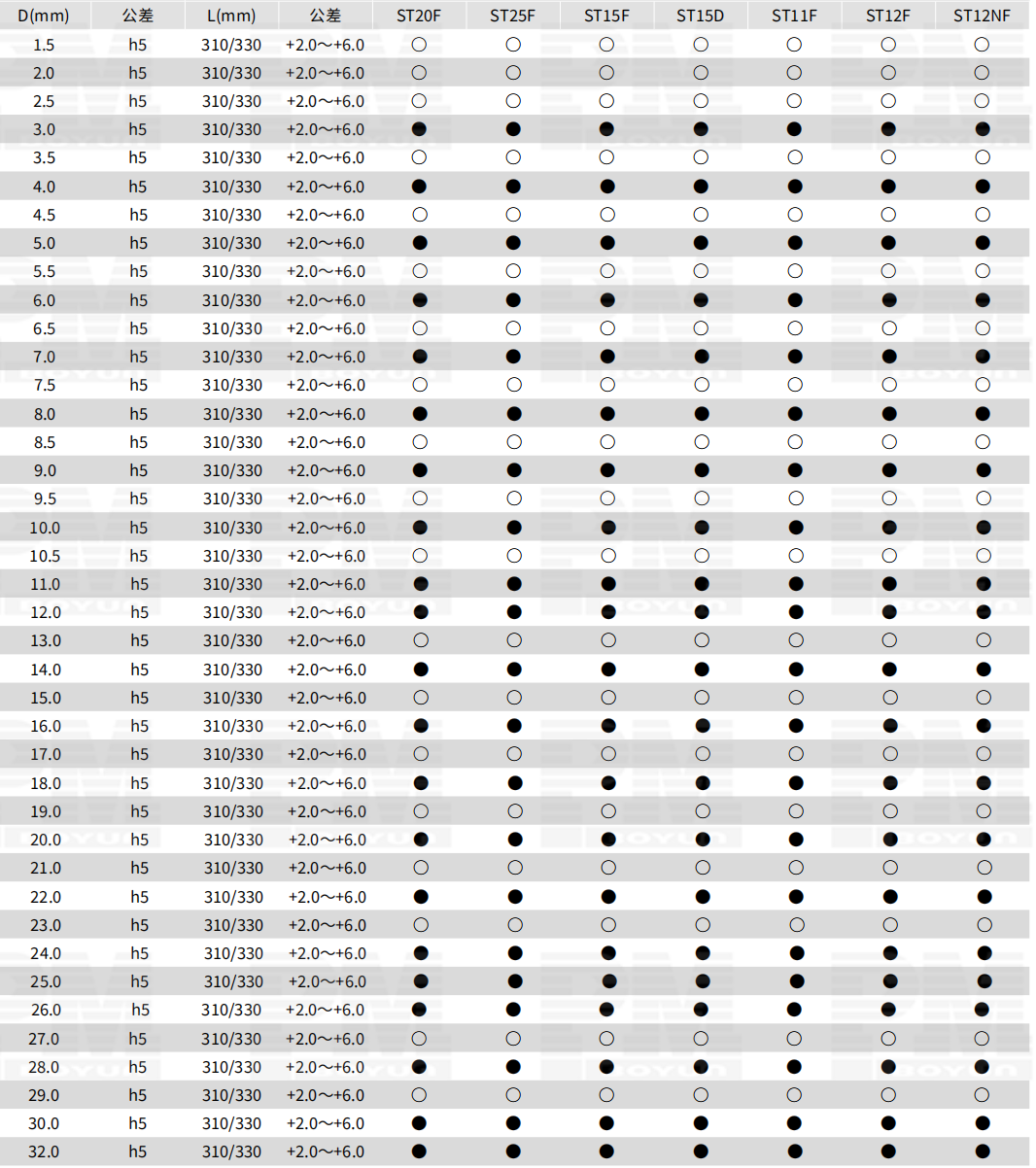

Referenzgréissten

Materialgradtabell

| Aféierung an Hartmetallstangen | |||||||

| Grad | Co-% | WC Kärgréisst | HRA | HV | Dicht (g/cm³) | Biegefestigkeit (MPa) | Bruchstäerkt (MNm-3/2) |

| KT10F | 6 | Submikron | 92,9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfein | 93,8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | Nanometer | 94,5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Gutt | 90,7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submikron | 92,3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfein | 93,5 | 1960 | 14,5 | 3000 | 9 |

| KT12F | 9 | superfein | 93,5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | Nanometer | 94,2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submikron | 91,2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submikron | 92,0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submikron | 91,7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submikron | 92,0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfein | 92,4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfein | 92,2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfein | 91,5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | Nanometer | 92,0 | 1670 | 13.8 | 4800 | 10 |

Schreift Är Noriicht hei a schéckt se eis